Laser Welding Equipment

Carry out laser welding for hermetically sealed products with air tightness requirements, and strictly control the moisture and oxygen content in the sealed box. The air tightness level meets the industry standard and can also meet the customized requirements of customers.

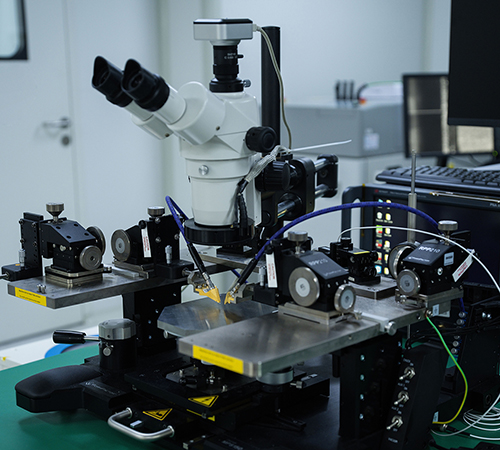

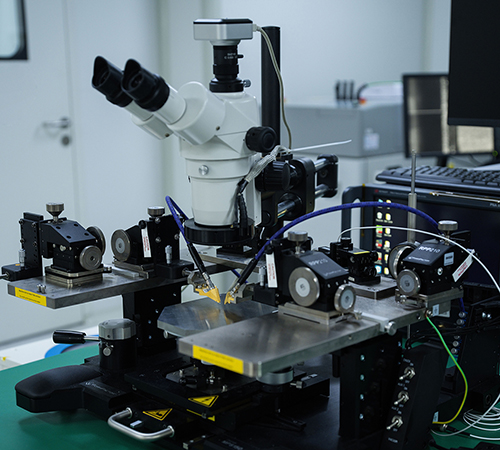

Probe Station

Before die packaging, use probe station to test the die performance and select so as to ensure the product consistency and excellent performance after packaging.

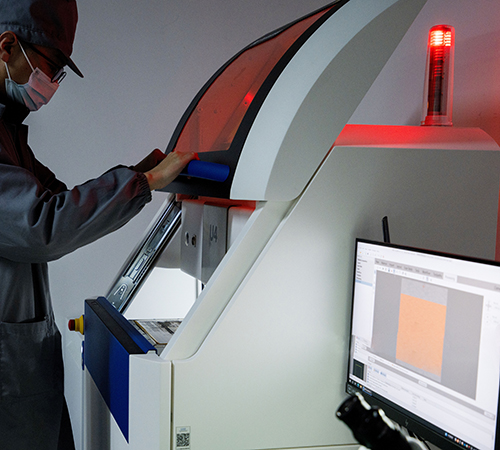

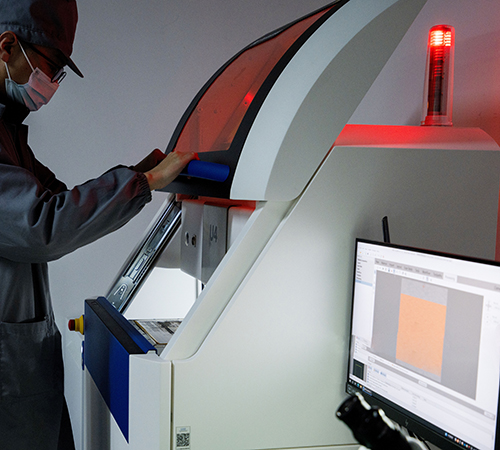

Laser PCB Making Machine

Use laser for RF PCB making and cutting, with accuracy up to ±0.02mm, so as to meet the manufacturing requirements of RF components with high frequency and best performance.

Vacuum Soldering System

Multi-chip vacuum soldering system can meet the requirements of mass production. And strictly control the soldering quality to ensure good heat dissipation and shear force of each chip.