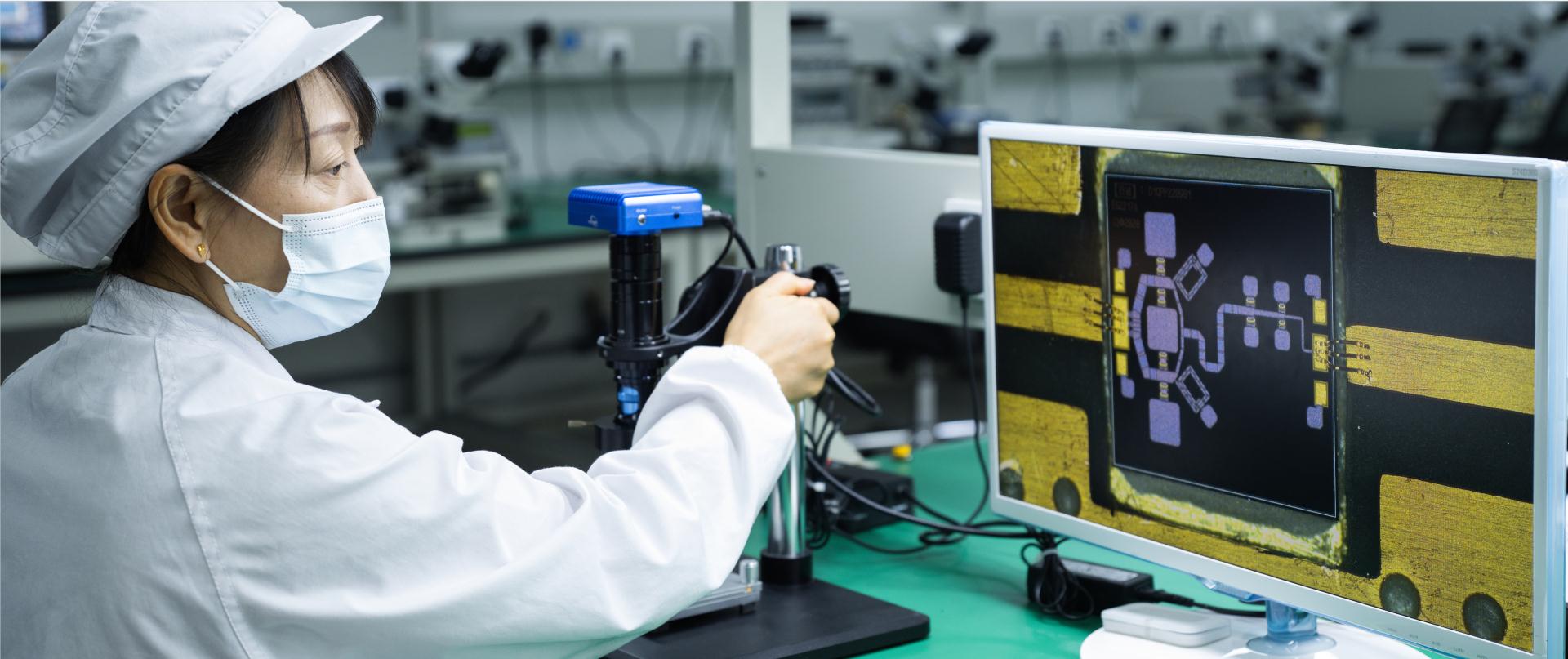

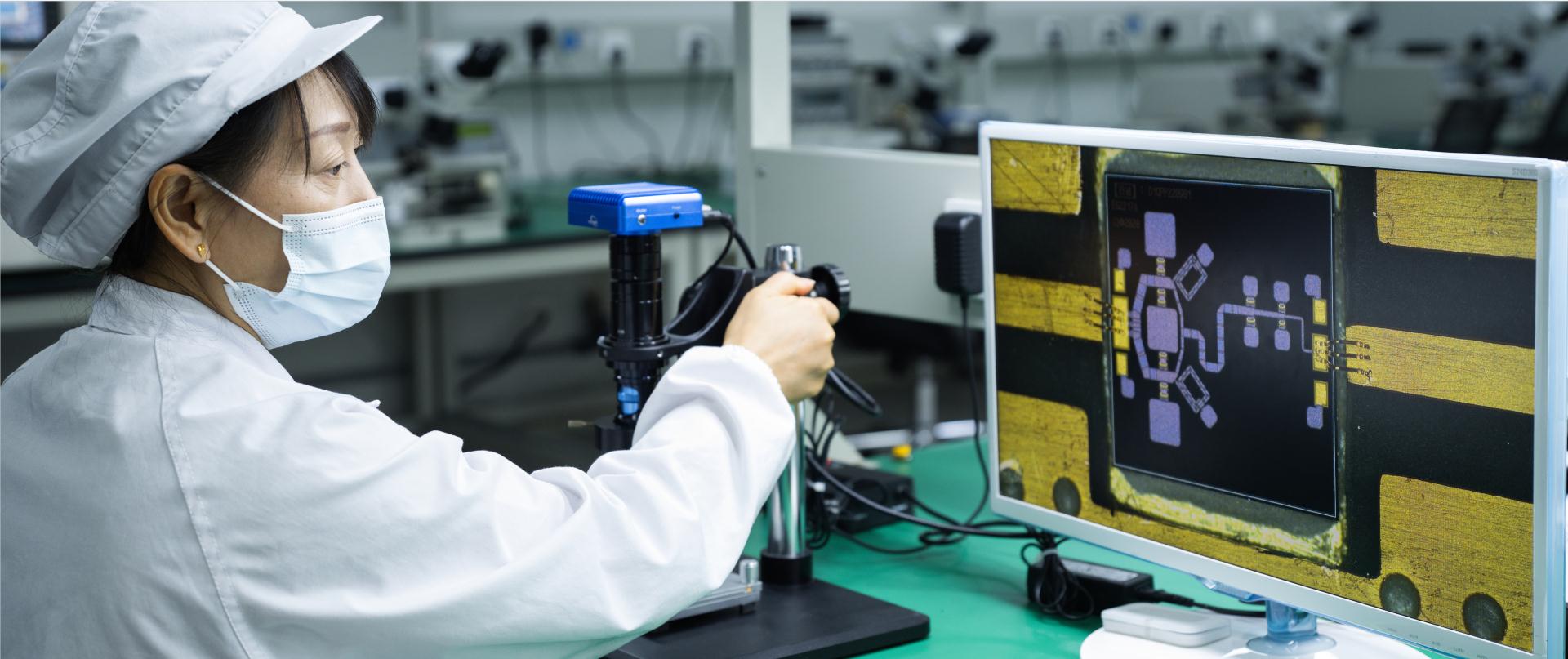

QA and QC

We strictly adhere to ISO9001 quality system, and formulate strict quality inspection standards from incoming material inspection, process inspection to finished product testing and inspection to ensure that each process 100% meets the standard and all the products are qualified. Meanwhile, each product can be traced by serial number.

Air Tightness Test

For products with air-tightness requirements, we conduct air-tightness test on each product after laser-sealing to ensure that it meets industry standards or separate requirements of customers.

Heat Detection

The heating and heat dissipation of components in operation must be considered when designing products. During product research and development, our engineers are conducting temperature detection on heating components to ensure good heat dissipation and product stability through design.

Automatic Test of Finished Products

Our self-developed automatic test software system can automatically determine whether the product indicators meet the standard, which improves the test efficiency and accuracy. And the test curve of each outgoing product is also recorded.